Before making landscape boulders, you need to design the shape and then make adjustments in the middle of the structural design drawings. There are many details. After completing the above content, you can make, splice, install, process, grind and other processes. What is the craftsmanship of landscape boulders? How to color?

1. The cleanliness of the metal surface seriously affects the bonding force of the coating and the spray paint layer. Foreign matter such as water and oil stains remaining or adsorbed on the surface of the part is eliminated and unclean. Failures such as pinholes, tumors, peeling or poor combination often occur.

2. Based on material considerations, after phosphating treatment, painting should be carried out in a timely manner within no more than 24 hours. After steel parts are sandblasted, they must be painted within 6 hours. This process measure is a practical way to help improve the adhesion between the coating layer and the substrate and improve its corrosion resistance.

3. The oil-water separation in the compressed air is insufficient, causing the compressed air to contain too much water and oil, which will inevitably affect the quality of the coating film and cause various faults and defects. Therefore, it is helpful to improve the performance of the coating spray layer, regularly replace the filter in the oil-water separation facility, and keep the compressed air clean.

4. The temperature of the spray painting site. Humidity has a significant impact on the quality of paint coating films. It should be noted that the temperature at the paint construction site should be maintained within the range of 10~30°C, and the relative humidity should not exceed 80%. The construction site must be kept clean and hygienic. Clean and orderly, the temperature is too high, the relative humidity is high, the paint coating is easy to turn white, showing orange skin, etc. If the temperature is too low, the paint layer will flow easily, which will have a negative impact on the coating quality of the coated metal surface.

5. Air spraying is generally used for metal surface spraying operations. Pay attention to keeping the distance between the spray gun and the surface to be sprayed within the range of 200~300mm, and control the compressed air pressure within the range of 2~4kg/cm, so as to effectively ensure the quality of spray painting.

6. Acid chemical color

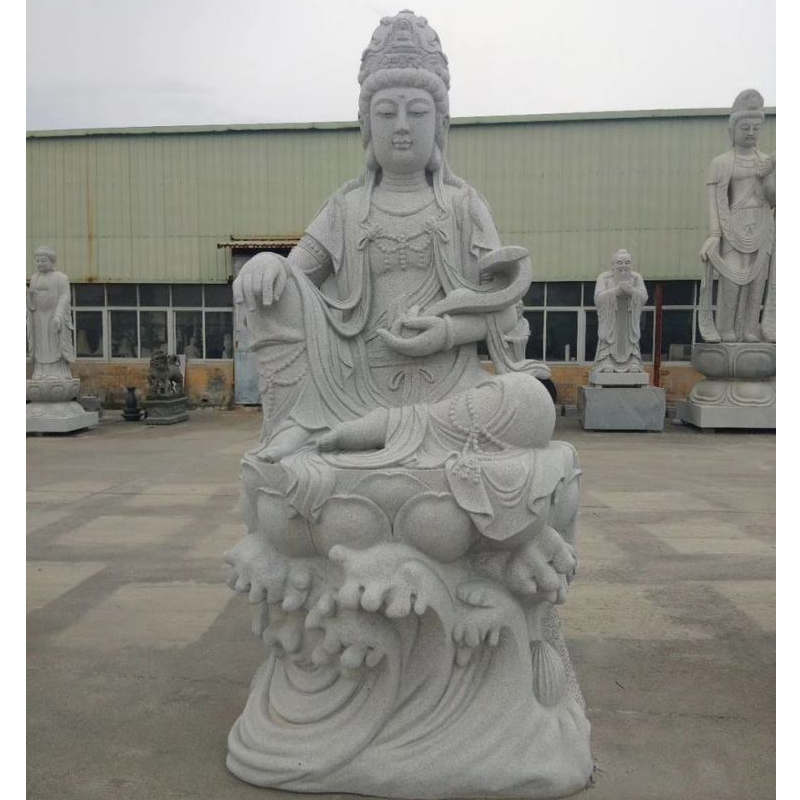

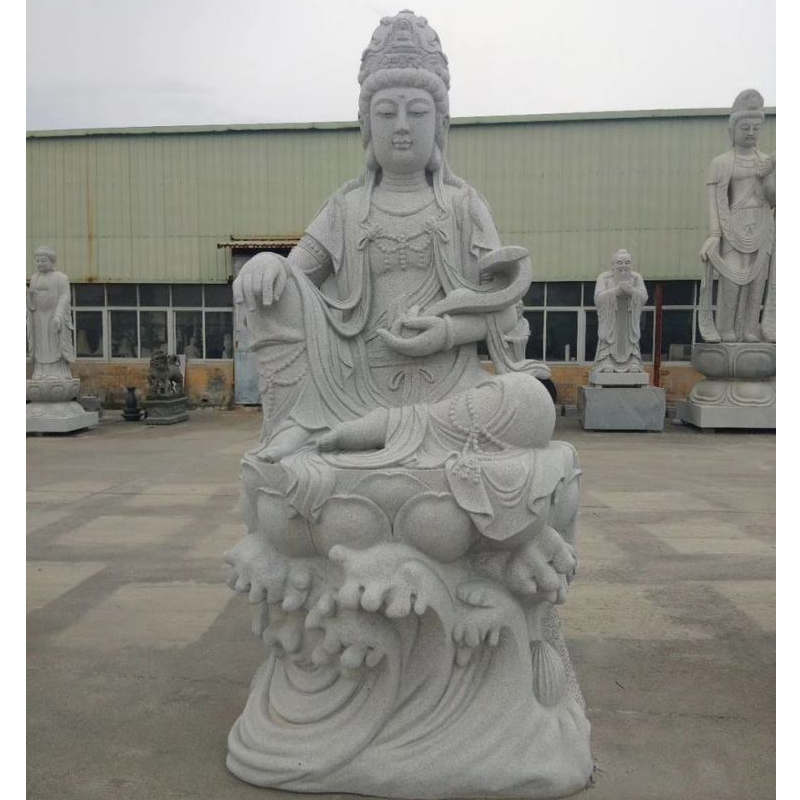

stone sculpture are loved by people for their beautiful colors and excellent performance.

The advantages of acid chemical coloring are the preparation of stone sculpture with more colors, fast speed, high degree of industrialization, high temperature, bright colors, good reproducibility, and not affected by the shape of the workpiece. However, the colored stone sculpture obtained by this method are still monochromatic. Lacks beauty. Poor coating uniformity. Highly toxic. Strong acidity. Color aging solutions have complex ingredients.

7. Use the continuous coloring method to prepare color images on the surface of stone sculpture, and study the potential of continuous coloring and single-color coloring of different colors. Colored area. Effects of print color and surface concealment on continuous coloration. On this basis, combined with network printing technology, images of different colors can be obtained on the surface of stone sculpture. The results show that multi-color continuous color potential changes and single-color continuous color potential changes, the smaller the background color difference, the more color continuous color varieties, and the color gamut And surface hiding does not affect the color change of the continuous color potential, but the hidden defects will be extended after the coating time, and various colors of continuous colors have a simple process. Color is adjustable. The painting is gorgeous.